The Silicon Carbide Reaction Sintering Furnace is a new type of furnace newly developed by our company. It has high temperature control accuracy of ≤0.1℃, good temperature uniformity of ±2℃, and the temperature can reach 2300℃. Small footprint and flexible turnover. Especially suitable for small batch production or laboratory use.

Product parameters

1. Model: YHGYL-THL45/45-50

2. Heating method: isostatic graphite resistance heating

3. Power control: low DC voltage, high current mode

4. The design power is 60KW, and the actual production power is not more than 50KW.

5. Power supply: three-phase five-wire system, three-phase 380V, frequency 50HZ

6. Design temperature: 2100℃, long-term common temperature is 2000℃;

7. Cooling method: natural cooling

8. Effective discharge space: 450mm wide, 450mm high, 500mm deep

9. Heating rate: When loading, the average heating rate below 1000℃ is 5℃/min, the average heating rate between 1000-1800℃ is 5℃/min, and the average heating rate between 1800-2250℃ is 3℃/min.

10. Temperature control accuracy: RT room temperature -2000℃≤±2℃

11. Power supply configuration: integrated with furnace body

12. Furnace body type: horizontal front door discharging

13. Working gas content in the furnace: vacuum or Ar, N2, NH? and other gases (slight positive pressure), vacuum replacement;

14. Temperature uniformity: ≤±3℃ (evaluated after 30 minutes of constant temperature);

15. Temperature measurement: single-zone tungsten sleeve tungsten-rhenium thermocouple temperature measurement

16. Temperature control: Japan Shimaden FP23, PID intelligent temperature controller program control (temperature control accuracy: ±0.1℃) and manual control;

17. Protection method: PLC+touch screen+sound and light alarm

18. Vacuum system configuration: 2H-70 slide valve pump

19. Vacuum measurement: resistance + capacitance film vacuum gauge, measuring range 0-105pa

20. Pressure rise rate: vacuum to 5Pa, stop the pump for 30 minutes and start timing, pressure rise per hour ≤ 10P

21. Cold ultimate vacuum degree: ≤5Pa (in clean, cold, empty furnace state)

22. Empty furnace vacuuming time ≤20min (empty furnace, room temperature, refer to GB/T10066.1-2004 for testing.)

23. Maximum pressure in the furnace 0.02Mpa

24. Explosion-proof valve trip pressure: 0.07Mpa

25. Cooling system: All circulating water pipes are well sealed and there is no leakage during use;

26. Electrical control: Siemens PLC + Delta 15-inch touch screen. Key parameters such as vacuum, temperature, and power can be queried in real time and historically, and can be exported through a USB flash drive and set up a paperless recorder.

27. Imported materials are used for key components, such as temperature control instruments and thermometers.

28. Opening method: manual

29. Material entry and exit method: equipped with special entry and exit trucks

30. Paint color: main body milky white, frame sky blue, base black

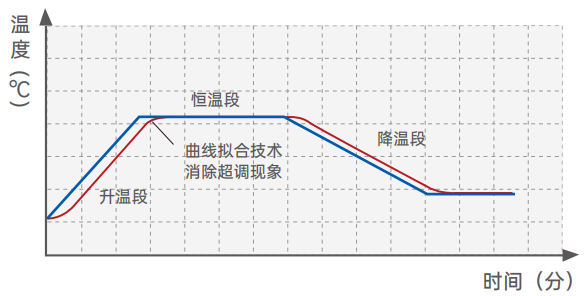

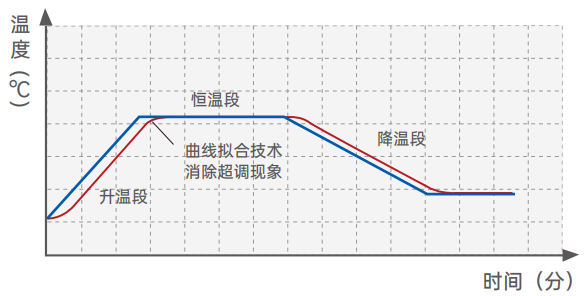

In view of the serious temperature rise lag in the low-temperature section of the furnace, multi-stage AI self-learning PID and temperature control curve fitting technology are used to make the temperature control accuracy in the low-temperature section and high-temperature section consistent, reaching ≤±2°C.

Product Characteristics

1. The maximum working temperature is 2300℃, and the common temperature is 2250℃.

2. Working atmosphere: air atmosphere, vacuum sintering or reducing atmosphere sintering (slight positive pressure)

3. Temperature measurement: thermocouple and far-infrared optical temperature measurement component form

4. Temperature control: program control and manual control; Temperature control accuracy: ±0.1℃

Product Showcase